Have Specs Ready? Send Us Your RFP for a Fast, Competitive Quote.

Save Big on 36×48 Sheets – Better Yields, Lower Shipping.

Shop Stainless Tubing – Huge Selection, Lower Shipping Rates.

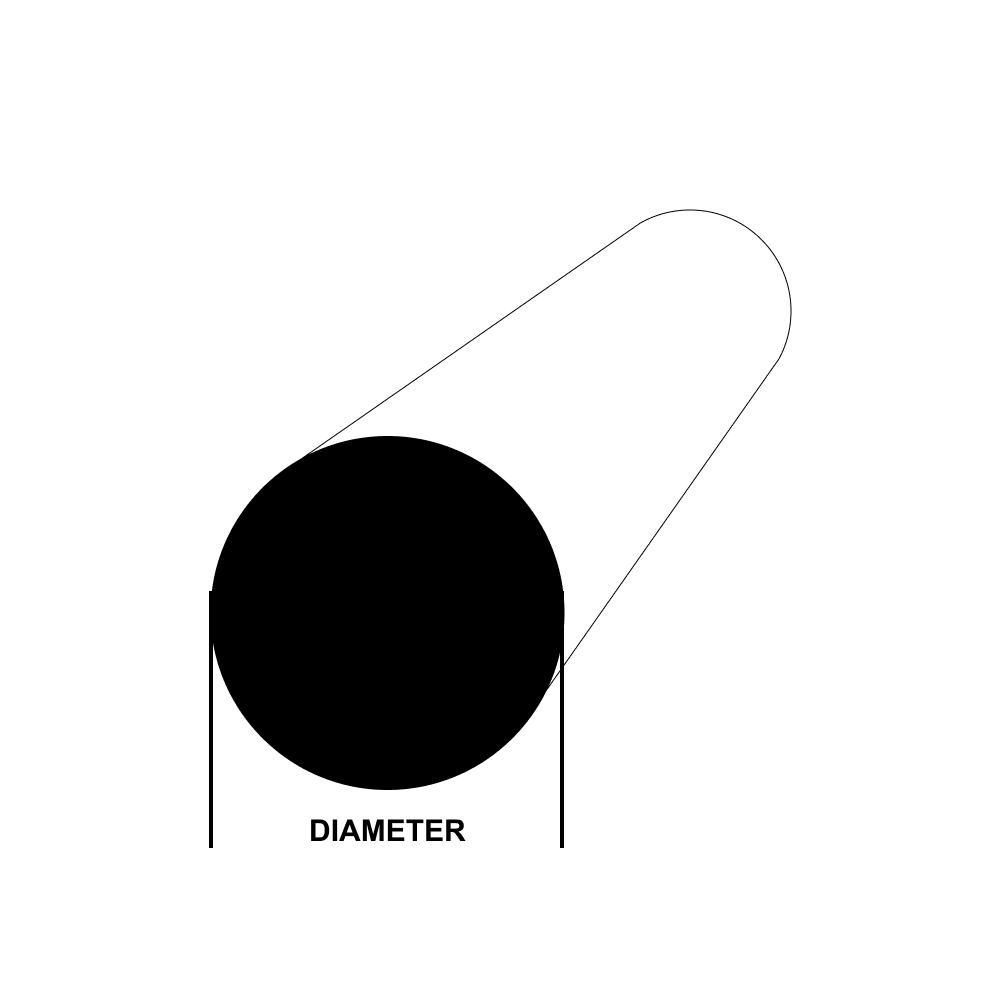

3/4 inch Aluminum Round Bar 6262-T6511 has superior corrosion resistance, excellent machinability, good strength, and good corrosion resistance. 6262 was specifically designed for applications that require significant machining, the addition of lead and bismuth helps lubricate the cutting tool. 6262 is typically used in camera parts, couplings, marine fittings, decorative hardware, hinge pins, knobs, nuts, oil line fittings, valves, and valve parts.

| Dimension Name | Specification |

| Diameter | 0.75 |

| Max Length | 168 |

| Alloy | 6262 |

| Temper | T6511 |

| Production Method | Extruded |

| Material | Aluminum |

| Shape | Bar-Round |

| MTR Availability | Yes |

| RoHS | Yes |

| REACH | Yes |

| Custom Cut Warehouse | 1 |

This material meets the following specs: ASTM- B221

| Weight/Lineal Foot | ||

| 0.53 pounds |

| Mechanical Properties | |

| Property | Value |

| Ultimate Tensile Strength KSI | 43 |

| Brinell Hardness 500 kg load | 71 |

| Yield Tensile Strength KSI | 39 |

| Density g/cm^3 | 3 |

| Rockwell Hardness B Scale | 36 |

| Elongation % in 2 in. | 10 |

| Melting Point °F | 1080 - 1205 |

| Machinability % | 70 |

| Electrical Conductivity % IACS | 44 |

| Shear Strength KSI | 26 |

| Chemistry Information: 6262 Aluminum | |

| Element | Percentage |

| Al | 94.6 - 97.8 |

| Bi | 0.4 - 0.7 |

| Cr | 0.04 - 0.14 |

| Cu | 0.15 - 0.4 |

| Fe | 0.7 max |

| Pb | 0.4 - 0.7 |

| Mg | 0.8 - 1.2 |

| Mn | 0.15 max |

| Si | 0.4 - 0.8 |

| Ti | 0.15 max |

| Zn | 0.25 max |