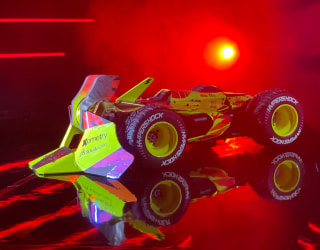

General & Combat Robotics

We proudly support general robotics (such as FIRST Robotics), combat robotics (such as BattleBots), and STEM programs across the US with large or small quantities of cut-to-size materials delivered directly to your door.

"Online Metals is Team Valkyries' first stop when scoping out raw materials to build our BattleBot because of their wide range of materials and sizes to choose from.”

– Team Valkryie, BattleBots

SHOP

Learn

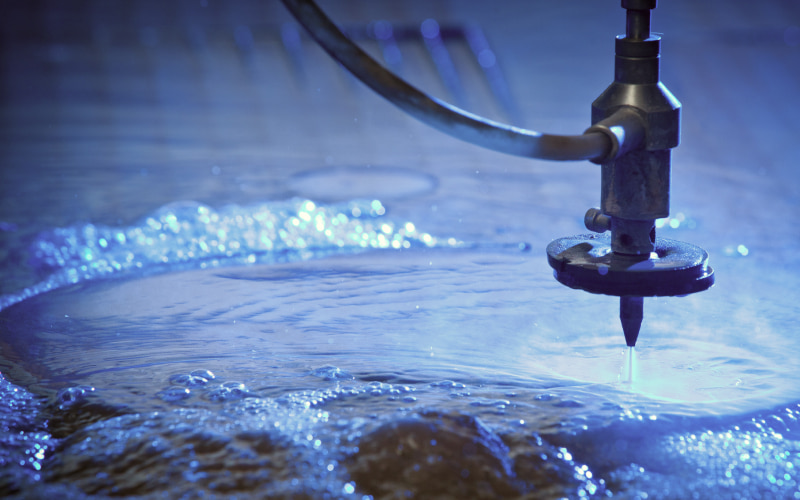

Need Waterjet Parts For Your Robot?

Now offering precision custom cuts with fast turnaround for your next robot build!

TEAMS

FAQ

Combat robotics (such as BattleBots) is a head-to-head competition in which robots must be designed to both deliver blows powerful enough to disable opposing robots and be able to take blows without faltering as well.

The main materials we provide that are heavily used in combat robotics are Aluminum (6061, 5052, and 2024), Titanium Grade 2, Alloy Steel (4130 or 4140), AR500 steel, S7 Tool Steel, & UHMW. We have a few great articles that go much more in depth into why and when to choose each material.

The most common metals used in robot buildings consist of Aluminum, Titanium, and Steel. Depending on the intended responsibilities of the robot, you will need to balance your goals in terms of weight, strength & durability, and machinability. Metal will often serve as the structure, base, or armor/weapon in combat robotics.

The two most used metals for a robot chassis are Aluminum and Steel.

- Aluminum is one of the lighter and softer metals which provides great machinability and handles the elements well.

- Steel is the hardest and strongest material for building your chassis. Steel is relatively cheap, handles abuse well, is thermally conductive (though not as conductive as aluminum) and welding steel is easy in comparison to aluminum.

Depending on the robot's weight and intended use there are a variety of different plastics you could utilize:

- Acrylic may be suitable for low-stress structural parts such as robot bodies.

- Polycarbonate is considerably stronger than acrylic, and PVC plastic is easy-to-process.

- Acetal resin, an engineering plastic, is both dense and strong.

- UHMW can be used for low-friction surfaces like skid pads and sliding joints, as well as for tough, impact and abrasion resistant components designed to take a hit.

Continue modifying your quoted cart?

Continue modifying your quoted cart?