Accepting orders 24/7. We'll resume shipping on July 5th

Serving global customers with custom-cut metals and trusted delivery.

Have Specs Ready? Send Us Your RFP for a Fast, Competitive Quote.

Aluminum Rectangle Bar 6061-T6511 exhibits above average corrosion resistance, good machinability, high strength, light weight, good weldability, and the ability to be heat treated for even higher strength, all at an affordable price. 6061 is the most commonly used aluminum alloy in the world due to its positive characteristics. It is typically used in aerospace, automotive, cameras, couplings, marine hardware, electrical components, decorative hardware, structural applications, pins, brakes, pistons, valves, and bicycle frames.

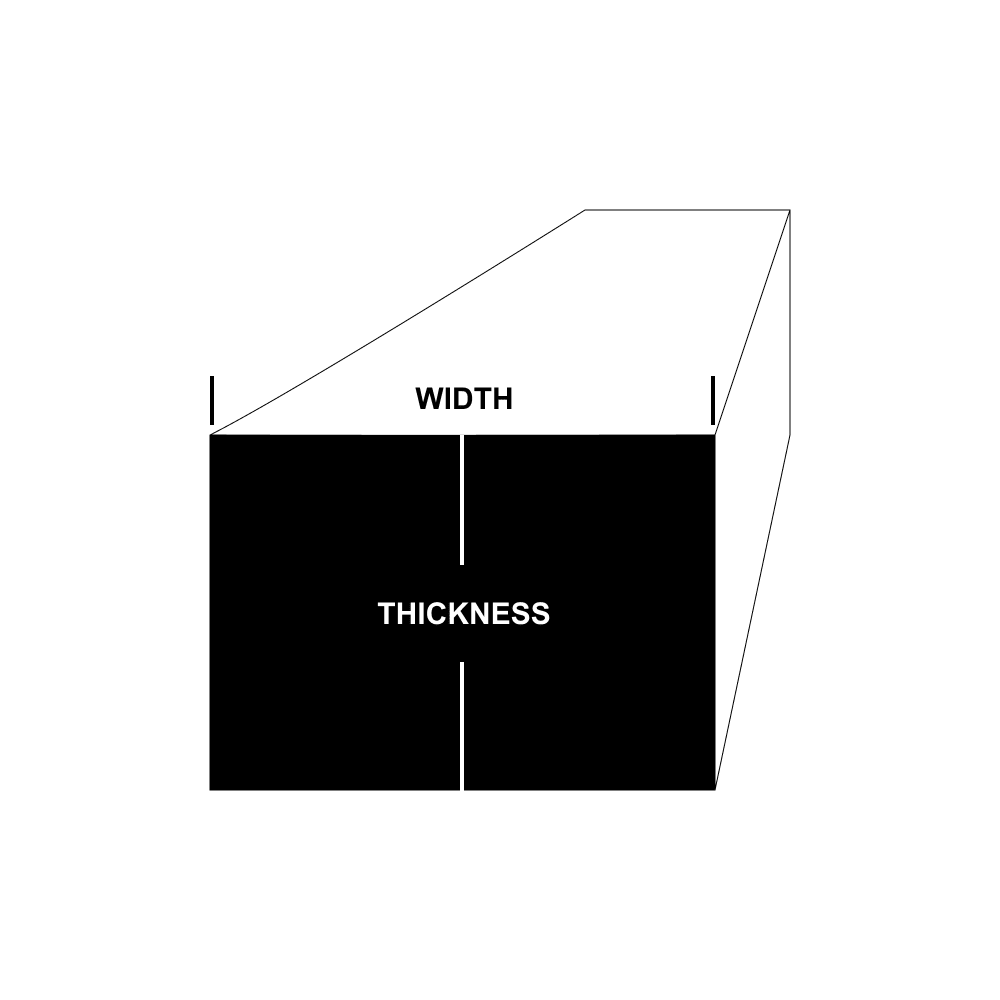

| Dimension Name | Specification |

| Thickness | 0.25 |

| Width | 2 |

| Max Length | 144 |

| Alloy | 6061 |

| Temper | T6511 |

| Production Method | Extruded |

| Material | Aluminum |

| Shape | Bar-Rectangle |

| MTR Availability | Yes |

| RoHS | Yes |

| REACH | Yes |

| Custom Cut Warehouse | 1 |

This material meets the following specs: ASTM- B221, AMS- QQ-A-200/8

| Weight/Lineal Foot | ||

| 0.59 pounds |

| Mechanical Properties | |

| Property | Value |

| Ultimate Tensile Strength KSI | 42 |

| Density g/cm^3 | 3 |

| Yield Tensile Strength KSI | 40 |

| Brinell Hardness 500 kg load | 93 |

| Melting Point °F | 1080 - 1205 |

| Elongation % in 2 in. | 9 |

| Rockwell Hardness B Scale | 59 |

| Machinability % | 50 |

| Shear Strength KSI | 25 |

| Electrical Conductivity % IACS | 43 |

| Chemistry Information: 6061 Aluminum | |

| Element | Percentage |

| Al | 98 |

| Cr | 0.04 - 0.35 |

| Cu | 0.15 - 0.4 |

| Fe | 0.7 max |

| Mg | 0.8 - 1.2 |

| Mn | 0.15 max |

| Si | 0.4 - 0.8 |

| Ti | 0.15 max |

| Zn | 0.25 max |