Have Specs Ready? Send Us Your RFP for a Fast, Competitive Quote.

Save Big on 36×48 Sheets – Better Yields, Lower Shipping.

Shop Stainless Tubing – Huge Selection, Lower Shipping Rates.

Tool Steel Drill Rod H13 offers high toughness and very good stability during heat treatment. H13 provides good wear resistance in hot and cold work tooling. It is typically used in cores, cavities for dies, and tools that require toughness and polishability.

| Dimension Name | Specification |

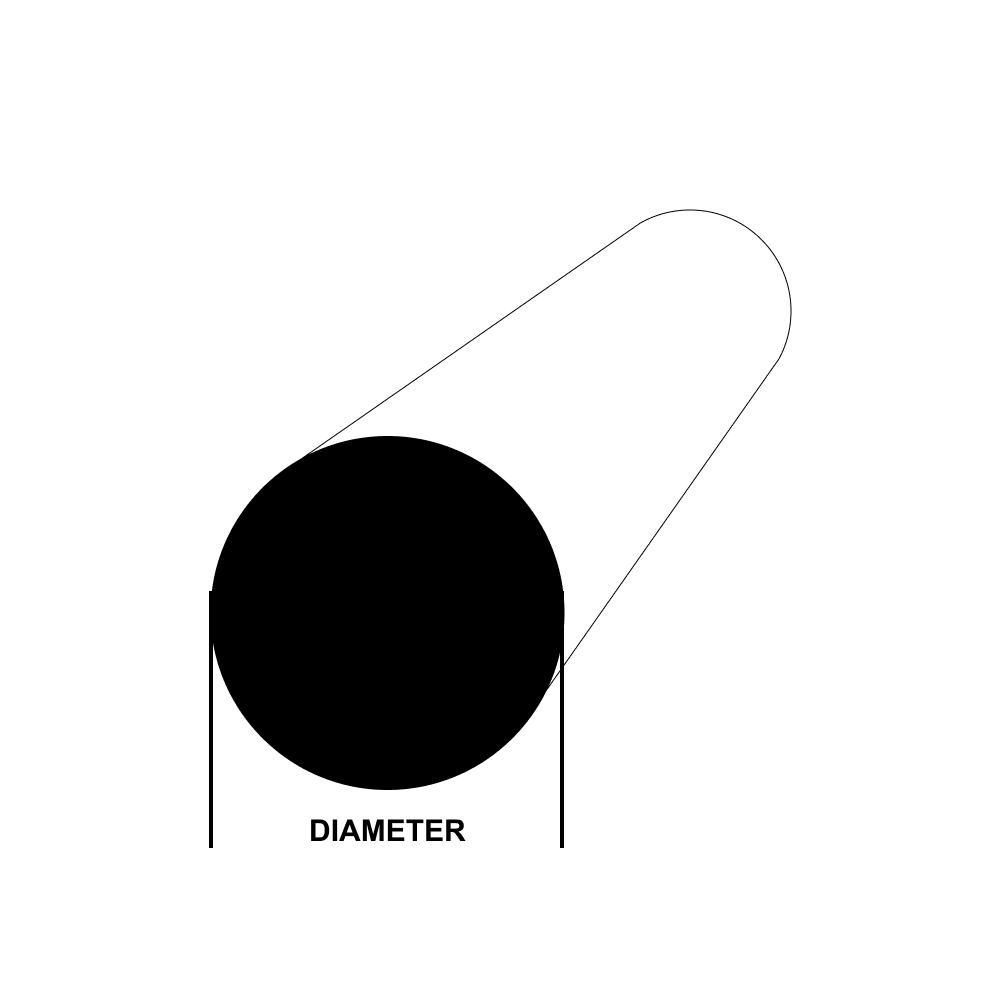

| Diameter | 0.5625 |

| Max Length | 36 |

| Alloy | H13 |

| Temper | Pre-Hard |

| Production Method | Precision Ground |

| Material | Tool Steel |

| Shape | Drill Rod |

| MTR Availability | Yes |

| Eniteo Vendor ID | 3145 |

| Custom Cut Warehouse | 0 |

| Weight/Lineal Foot | ||

| 0.84 pounds |

| Mechanical Properties | |

| Property | Value |

| Density g/cm^3 | 8 |

| Brinell Hardness 3000 kg load | 373 - 456 |

| Ultimate Tensile Strength KSI | 260 |

| Yield Tensile Strength KSI | 232 |

| Rockwell Hardness C Scale | 40 - 48 |

| Elongation % in 2 in. | 11 |

| Melting Point °F | 2580 - 2660 |

| Machinability % | 75 |

| Electrical Conductivity % IACS | 8 |

| Chemistry Information: H13 Tool Steel | |

| Element | Percentage |

| Fe | 88.8 - 92 |

| Cr | 4.8 - 5.5 |

| Si | 0.8 - 1.2 |

| Mo | 1.1 - 1.8 |

| Mn | 0.2 - 0.5 |

| C | 0.32 - 0.45 |

| V | 0.8 - 1.2 |

| Cu | 0 - 0.25 |

| Ni | 0 - 0.3 |

| P | 0 - 0.03 |

| S | 0 - 0.03 |