Have Specs Ready? Send Us Your RFP for a Fast, Competitive Quote.

Save Big on 36×48 Sheets – Better Yields, Lower Shipping.

Shop Stainless Tubing – Huge Selection, Lower Shipping Rates.

Tool Steel Rectangle Bar O1 offers excellent dimensional stability during heat treatment, and otherwise decent attributes. O1 is an oil-hardening, general purpose tool steel. While not as strong or wear resistant as A-2 or D-2, it experiences significantly less distortion during the heat treating process. It is typically used in rolls, punches, shear knives, food processing knives, and gauges.

| Dimension Name | Specification |

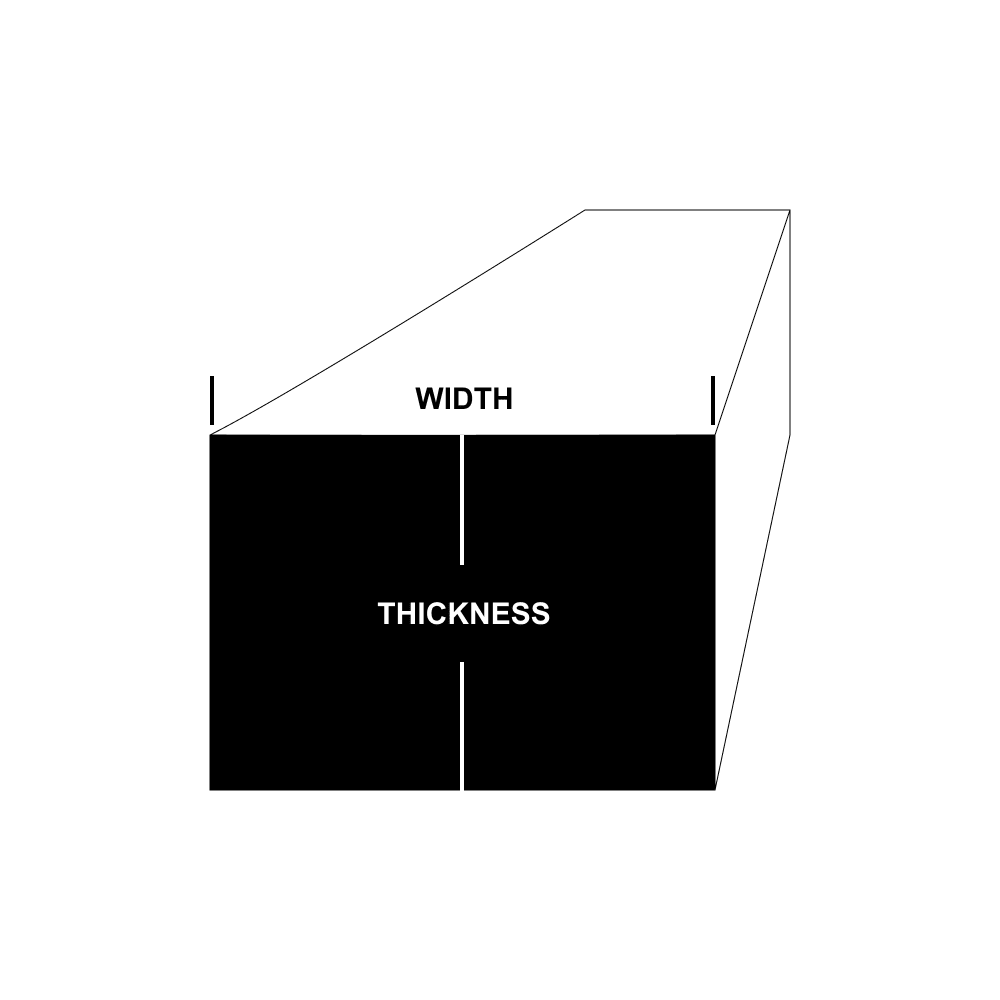

| Thickness | 0.015625 |

| Width | 1.25 |

| Max Length | 36 |

| Alloy | O1 |

| Production Method | Precision Ground |

| Material | Tool Steel |

| Shape | Bar-Rectangle |

| MTR Availability | Yes |

| Eniteo Vendor ID | 3145 |

| Custom Cut Warehouse | 0 |

This material meets the following specs: SAE- J-437, ASTM- A681

| Weight/Lineal Foot | ||

| 0.07 pounds |

| Mechanical Properties | |

| Property | Value |

| Density g/cm^3 | 8 |

| Ultimate Tensile Strength KSI | 105 |

| Elongation % in 2 in. | 20 |

| Melting Point °F | 2580 - 2660 |

| Yield Tensile Strength KSI | 58 |

| Brinell Hardness 3000 kg load | 177 - 212 |

| Rockwell Hardness B Scale | 88 - 95 |

| Shear Strength KSI | 58 |

| Machinability % | 95 |

| Electrical Conductivity % IACS | 7 |

| Chemistry Information: O1 Tool Steel | |

| Element | Percentage |

| C | 0.94 |

| Fe | 96.56 |

| Cr | 0.5 |

| Mn | 1.2 |

| Si | 0.3 |

| W | 0.5 |