Product Details, Specifications, and Technical Information

Stainless Round Bar 321 provides high strength, high temperature capability, and resistance to intergranular corrosion. 321 resists scaling at higher temperatures. Also, the addition of titanium means that welding is not suggested for this alloy. It is typically used in aerospace and defense for engine parts, heat exchangers, missile components, exhaust stacks, rocket engines, manifolds, and more.

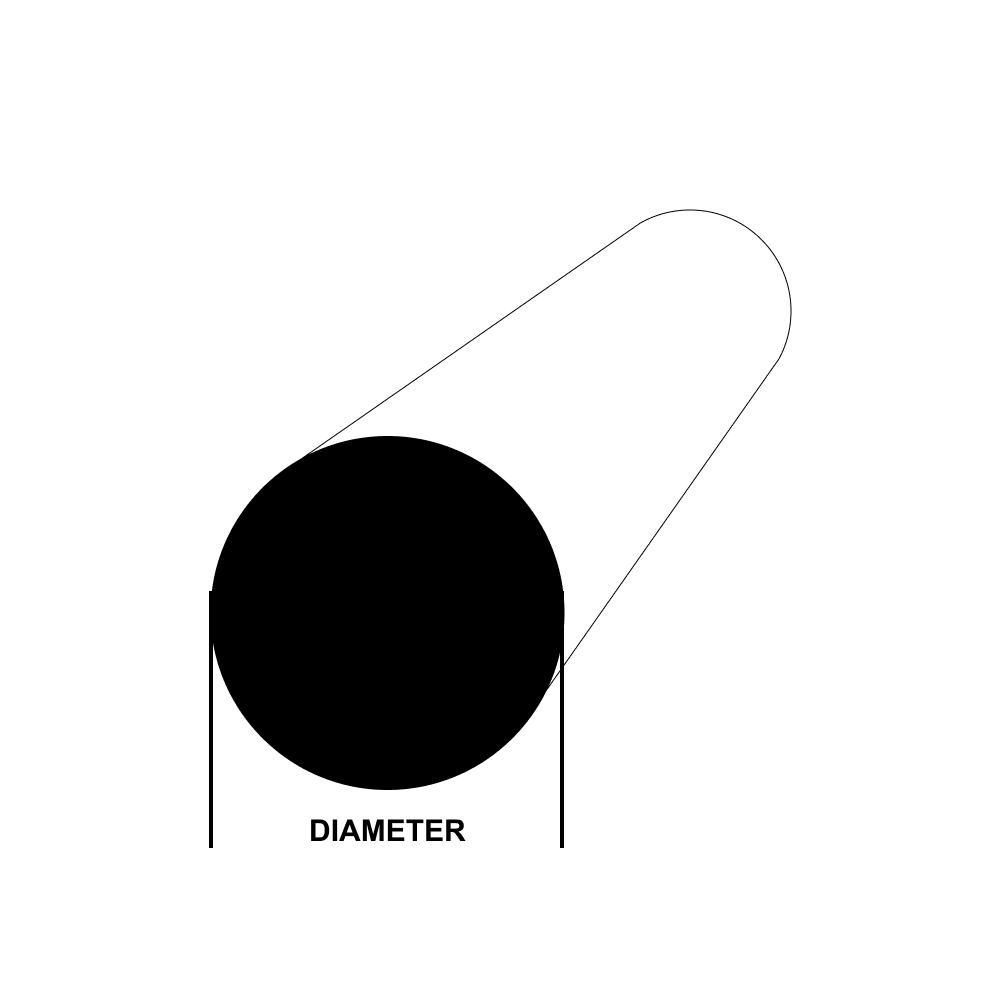

| Dimension Name | Specification |

| Diameter | 2.75 |

| Max Length | 144 |

| Alloy | 321 |

| Production Method | Cold Finished |

| MTR Availability | Yes |

| Material | Stainless Steel |

| Shape | Bar-Round |

| Custom Cut Warehouse | 1 |

This material meets the following specs: AMS -QQ-S-763, ASTM -A276, ASTM -A479, AMS -5645

| Weight/Lineal Foot | ||

| 20.31 pounds |

| Mechanical Properties | |

| Property | Value |

| Density g/cm^3 | 8 |

| Rockwell Hardness B Scale | 91 |

| Elongation % in 2 in. | 42 |

| Ultimate Tensile Strength KSI | 93 |

| Brinell Hardness 3000 kg load | 190 |

| Yield Tensile Strength KSI | 42 |

| Shear Strength KSI | 64 |

| Electrical Conductivity % IACS | 2 |

| Melting Point °F | 2550 - 2600 |

| Machinability % | 36 |

| Chemistry Information: 321 Stainless Steel | |

| Element | Percentage |

| C | 0.08 |

| Cr | 18 |

| Fe | 68 |

| Mn | 2 |

| P | 0.045 |

| S | 0.03 |

| Ni | 11 |

| Si | 1 |

| Ti | 0.15 |

Continue modifying your quoted cart?

Continue modifying your quoted cart?