Product Details, Specifications, and Technical Information

Stainless Rectangle Bar 17-4 offers high strength, hardness, corrosion resistance, and relative ease of machining. The combination of strong mechanical and fabrication properties make stainless 17-4 rectangle a versatile material for applications that require extensive machining and welding. It is typically used in gate valves, chemical processing equipment, pump shafts, gears, ball bearings, bushings, and fasteners.

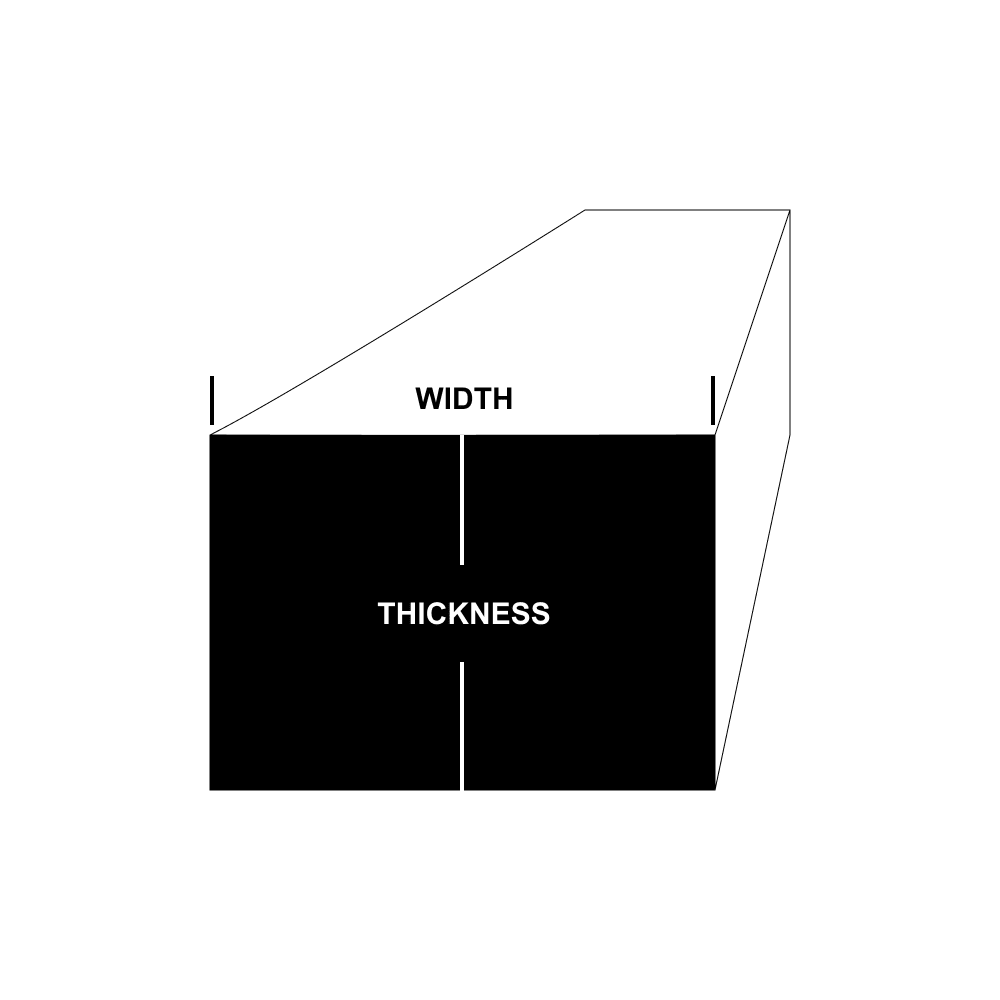

| Dimension Name | Specification |

| Thickness | 0.5 |

| Width | 3.5 |

| Max Length | 144 |

| Alloy | 17-4 |

| Temper | Condition A |

| Production Method | Hot Rolled |

| Material | Stainless Steel |

| Shape | Bar-Rectangle |

| Grade | PH |

| Surface | Pickled |

| MTR Availability | Yes |

| RoHS | Yes |

| REACH | Yes |

| Custom Cut Warehouse | 1 |

| Weight/Lineal Foot | ||

| 6.09 pounds |

Please note that this data is to be used ONLY FOR REFERENCE, NOT FOR DESIGN, and by using it,you agree that any decisions you make regarding materials for your project are at your own discretion.

| Mechanical Properties | |

| Property | Value |

| Density g/cm^3 | 8 |

| Brinell Hardness 3000 kg load | 363 max |

| Rockwell Hardness C Scale | 39 max |

| Melting Point °F | 2550 - 2620 |

| Yield Tensile Strength KSI | 145 |

| Ultimate Tensile Strength KSI | 160 |

| Elongation % in 2 in. | 6 - 15 |

| Machinability % | 45 |

| Electrical Conductivity % IACS | 2 |

| Chemistry Information: 17-4 Stainless Steel | |

| Element | Percentage |

| C | 0.07 max |

| Cu | 3 - 5 |

| Cr | 15 - 17.5 |

| Fe | 73 |

| Mn | 1 max |

| Nb + Ta | 0.15 - 0.45 |

| Nb | 0.45 max |

| Ni | 3 - 5 |

| P | 0.04 max |

| S | 0.03 max |

| Si | 1 max |

| Ta | 0.45 max |

Continue modifying your quoted cart?

Continue modifying your quoted cart?