Have Specs Ready? Send Us Your RFP for a Fast, Competitive Quote.

Save Big on 36×48 Sheets – Better Yields, Lower Shipping.

Shop Stainless Tubing – Huge Selection, Great Deals.

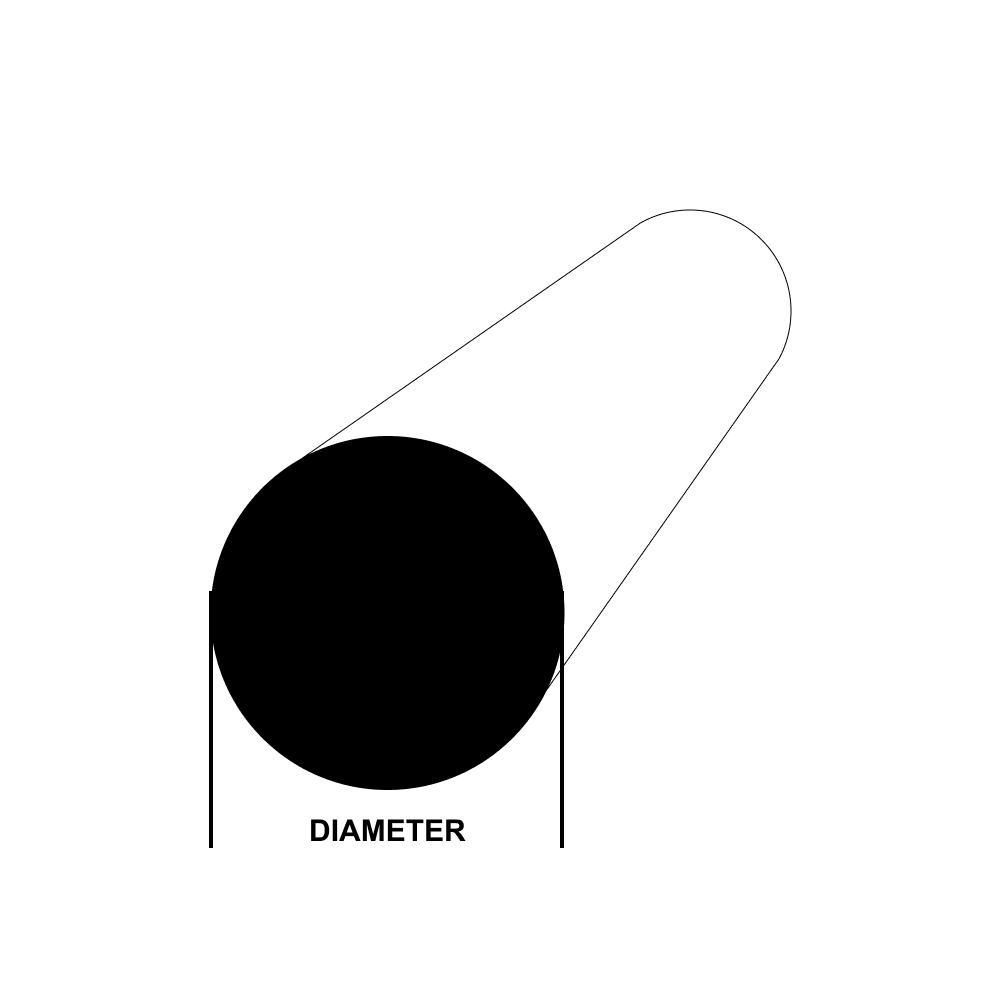

1" Nickel Alloy 718 Round Bar has both high strength properties and good corrosion resistance and weldability. It is commonly used for valves, fasteners, tubing materials and mandrels. Alloy 718 has excellent cryogenic and heat ranges. It is heat treatable, has moderately good corrosion resistance, weldability and formability.

| Dimension Name | Specification |

| Diameter | 1 |

| Max Length | 144 |

| Alloy | 718 |

| Temper | Annealed |

| Material | Nickel |

| Shape | Bar-Round |

| MTR Availability | Yes |

| RoHS | Yes |

| REACH | Yes |

| Custom Cut Warehouse | 1 |

This material meets the following specs: AMS- 5662, ASTM- B637(call for availability)

| Weight/Lineal Foot | ||

| 2.79 pounds |

| Mechanical Properties | |

| Property | Value |

| Ultimate Tensile Strength KSI | 145 max |

| Density g/cm^3 | 8 |

| Machinability % | 12 |

| Elongation % in 2 in. | 45 |

| Rockwell Hardness B Scale | 100 |

| Electrical Conductivity % IACS | 1 |

| Brinell Hardness 3000 kg load | 240 |

| Yield Tensile Strength KSI | 70 |

| Melting Point °F | 2410 - 2540 |

| Chemistry Information: 718 Nickel | |

| Element | Percentage |

| C | 0.08 max |

| Mn | 0.35 max |

| P | 0.015 max |

| S | 0.015 max |

| Si | 0.35 max |

| Cr | 17 - 21 |

| Ni | 50 - 55 |

| Mo | 2.8 - 3.3 |

| Nb | 4.75 - 5.5 |

| Ti | 0.65 - 1.15 |

| Al | 0.2 - 0.8 |

| Co | 1 max |

| Bo | 0.006 max |

| Cu | 0.3 max |

| Ta | 0.05 max |

| Fe | - |