Product Details, Specifications, and Technical Information

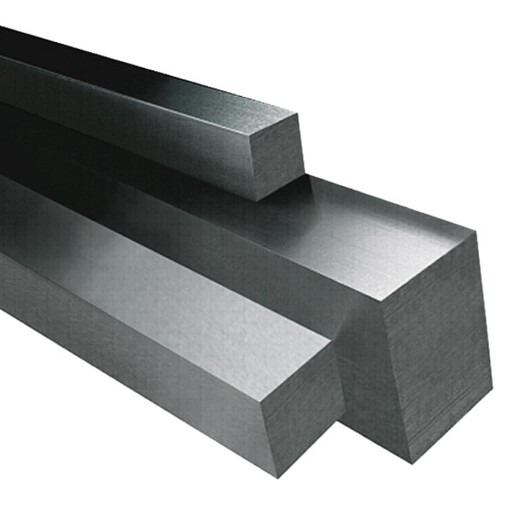

Cast Iron Rectangle Bar 65-45-12 Dura-bar offers high wear resistance, strength, durability, impact resistance, fatigue resistance, ductility, with excellent consistency and finish. 65-45-12 is comparably strong to 1040 steel in the "as-rolled" condition, and is manufactured through the Continuous Cast process, removing porosity and making it superior to other cast irons. It is typically used in the automotive and power industries for gears, rotors, pistons, valves, rollers, bushings, chucks, flywheels, pile drivers, rams pulleys, housings, and motorcycle disc brakes.

DURA-BAR is a trademark of Dura-bar

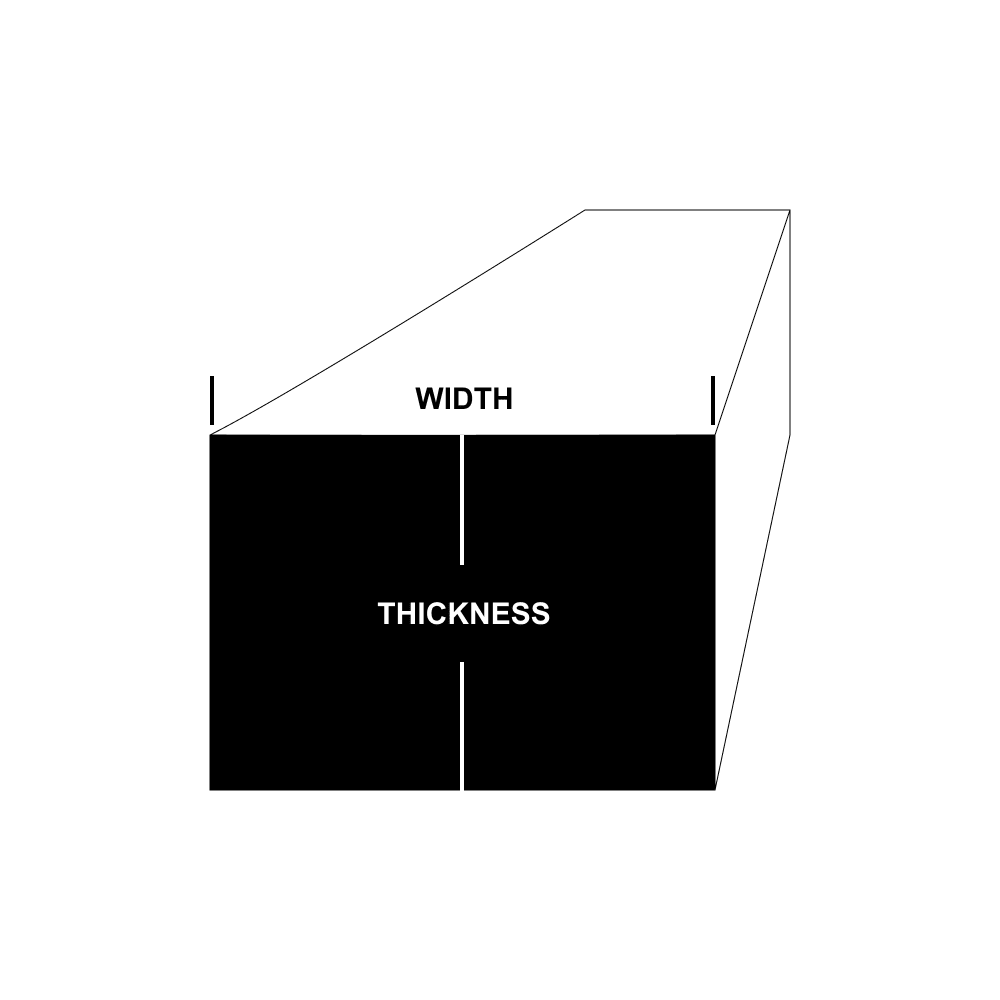

| Dimension Name | Specification |

| Thickness | 2.25 |

| Width | 4.25 |

| Max Length | 72 |

| Alloy | 80-55-06 |

| Production Method | As Cast |

| Material | Cast Iron |

| Shape | Bar-Rectangle |

| MTR Availability | Yes |

| Brand | Dura-Bar |

| Eniteo Vendor ID | 3109 |

| Custom Cut Warehouse | 1 |

| Weight/Lineal Foot | ||

| 30.75 pounds |

Please note that this data is to be used ONLY FOR REFERENCE, NOT FOR DESIGN, and by using it,you agree that any decisions you make regarding materials for your project are at your own discretion.

| Mechanical Properties | |

| Property | Value |

| Density g/cm^3 | 7 |

| Rockwell Hardness B Scale | 90 - 102 |

| Elongation % in 2 in. | 9 |

| Ultimate Tensile Strength KSI | 85 |

| Yield Tensile Strength KSI | 58 |

| Brinell Hardness 3000 kg load | 187 - 255 |

| Melting Point °F | 2050 - 2120 |

| Shear Strength KSI | 72 |

| Electrical Conductivity % IACS | 7 |

| Machinability % | 100 |

| Chemistry Information: 80-55-06 Cast Iron | |

| Element | Percentage |

| Ce | 0.005 - 0.2 |

| C | 3.6 - 3.8 |

| Cr | 0.03 - 0.07 |

| Cu | 0.15 - 1 |

| Mg | 0.03 - 0.06 |

| Fe | 90.738 - 94.175 |

| Mn | 0.15 - 1 |

| Mo | 0.01 - 0.1 |

| P | 0.03 max |

| Ni | 0.05 - 0.2 |

| Si | 1.8 - 2.8 |

| S | 0.002 max |

Continue modifying your quoted cart?

Continue modifying your quoted cart?