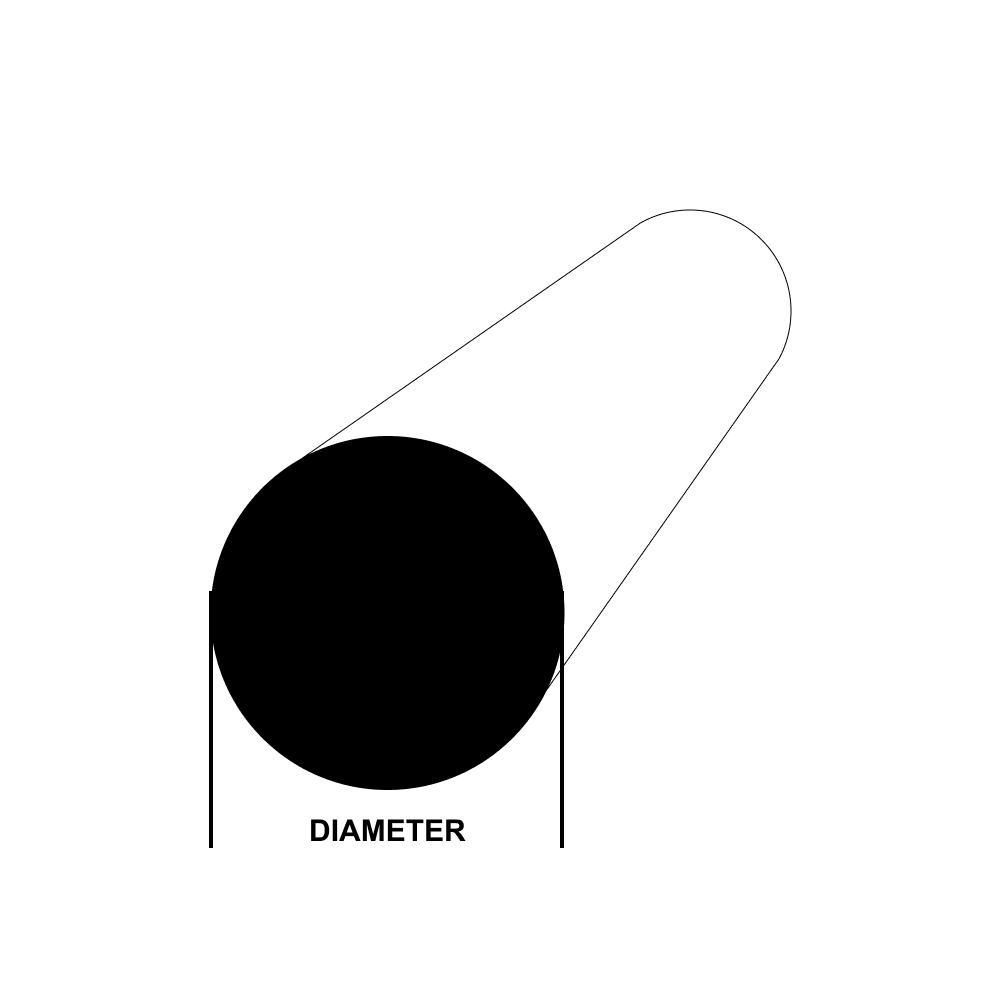

Product Details, Specifications, and Technical Information

Cold Roll Round Bar 1045 Cold Finish exhibits medium tensile strength, good weldability and machinability, and high strength. 1045 is a commonly used lower carbon steel with a wide range of applications. It is typically used in machinery parts, die forging, hot upsetting, gears, crankshafts, shafts, axles, bolts, studs, pinions, casters, and support plates.

| Dimension Name | Specification |

| Diameter | 3.25 |

| Max Length | 144 |

| Alloy | 1045 |

| Production Method | Cold Finish |

| Material | Carbon Steel |

| Shape | Bar-Round |

| MTR Availability | Yes |

| Custom Cut Warehouse | 1 |

| Weight/Lineal Foot | ||

| 28.16 pounds |

Please note that this data is to be used ONLY FOR REFERENCE, NOT FOR DESIGN, and by using it,you agree that any decisions you make regarding materials for your project are at your own discretion.

| Mechanical Properties | |

| Property | Value |

| Density g/cm^3 | 8 |

| Yield Tensile Strength KSI | 77 |

| Ultimate Tensile Strength KSI | 91 |

| Brinell Hardness 3000 kg load | 179 |

| Elongation % in 2 in. | 12 |

| Rockwell Hardness B Scale | 88 |

| Shear Strength KSI | 59 |

| Melting Point °F | 2590 - 2660 |

| Electrical Conductivity % IACS | 7 |

| Machinability % | 64 |

| Chemistry Information: 1045 Carbon Steel | |

| Element | Percentage |

| Fe | 98.7 |

| Mn | 0.8 |

| S | 0.05 |

| C | 0.45 |

| P | 0.04 |

Continue modifying your quoted cart?

Continue modifying your quoted cart?