Have Specs Ready? Send Us Your RFP for a Fast, Competitive Quote.

Save Big on 36×48 Sheets – Better Yields, Lower Shipping.

Shop Stainless Tubing – Huge Selection, Great Deals.

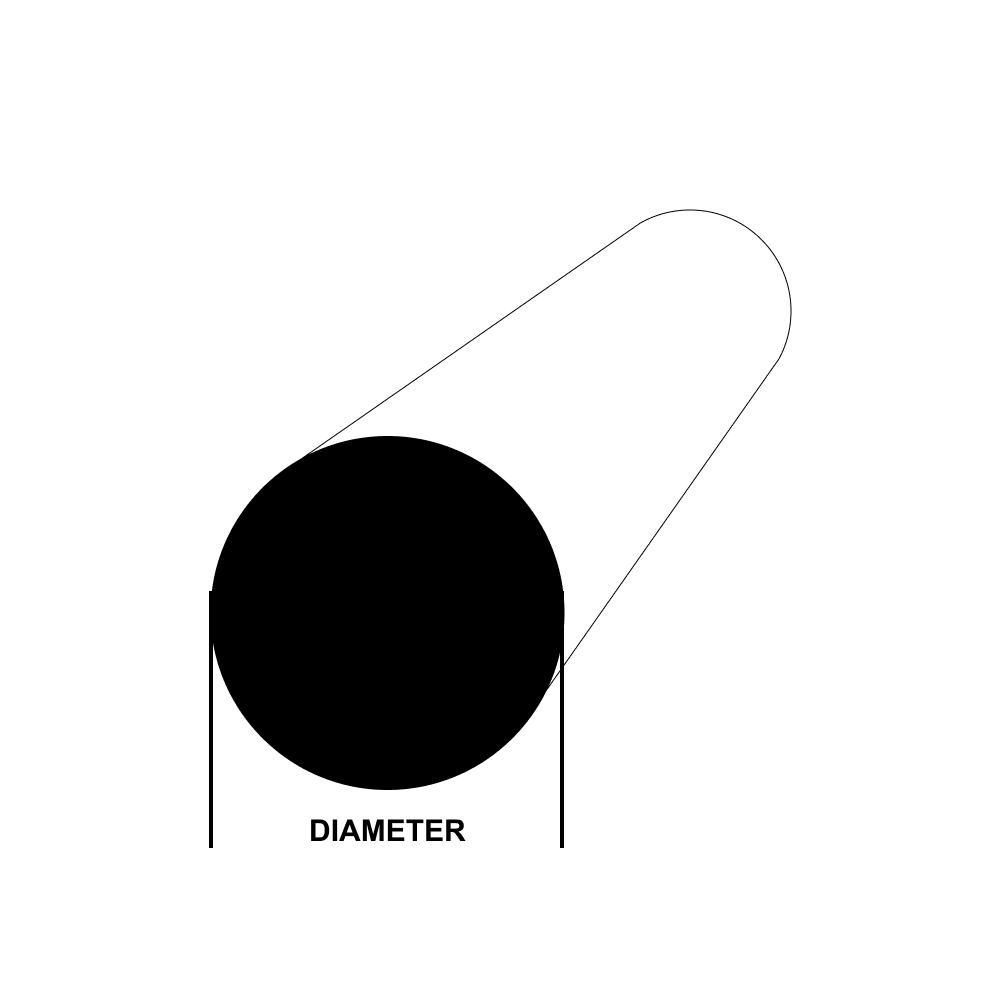

Cold Roll Round Bar 1045 Cold Finish exhibits medium tensile strength, good weldability and machinability, and high strength. 1045 is a commonly used lower carbon steel with a wide range of applications. It is typically used in machinery parts, die forging, hot upsetting, gears, crankshafts, shafts, axles, bolts, studs, pinions, casters, and support plates.

| Dimension Name | Specification |

| Diameter | 2.25 |

| Max Length | 144 |

| Alloy | 1045 |

| Production Method | Cold Finished |

| Material | Carbon Steel |

| Shape | Bar-Round |

| MTR Availability | Yes |

| Custom Cut Warehouse | 1 |

This material meets the following specs: ASTM- A108, ASTM- A29(call for availability)

| Weight/Lineal Foot | ||

| 13.5 pounds |

| Mechanical Properties | |

| Property | Value |

| Density g/cm^3 | 8 |

| Yield Tensile Strength KSI | 77 |

| Ultimate Tensile Strength KSI | 91 |

| Brinell Hardness 3000 kg load | 179 |

| Elongation % in 2 in. | 12 |

| Rockwell Hardness B Scale | 88 |

| Shear Strength KSI | 59 |

| Melting Point °F | 2590 - 2660 |

| Electrical Conductivity % IACS | 7 |

| Machinability % | 64 |

| Chemistry Information: 1045 Carbon Steel | |

| Element | Percentage |

| Fe | 98.7 |

| Mn | 0.8 |

| S | 0.05 |

| C | 0.45 |

| P | 0.04 |