Product Details, Specifications, and Technical Information

MoldMAX HH (High Hard) 1.25" beryllium copper round bar is the premier copper mold alloy. This alloy has a hardness and strength comparable with standard tool steels but its thermal conductivity is four to six times higher.

MoldMAX HH is used for injection mold cores and cavities and blow mold pinch-offs. Due to the unique combination of thermal conductivity and strength available in these copper mold alloys, you gain advantages like: shorter cycle time, improved plastic part dimensional control, better parting line maintenance, excellent corrosion resistance.

The high hardness of MoldMAX HH provides durability in applications where other high conductivity copper alloys fail. The alloy resists galling against other mold alloys, including itself.

MoldMAX is a trademark of Materion Corporation

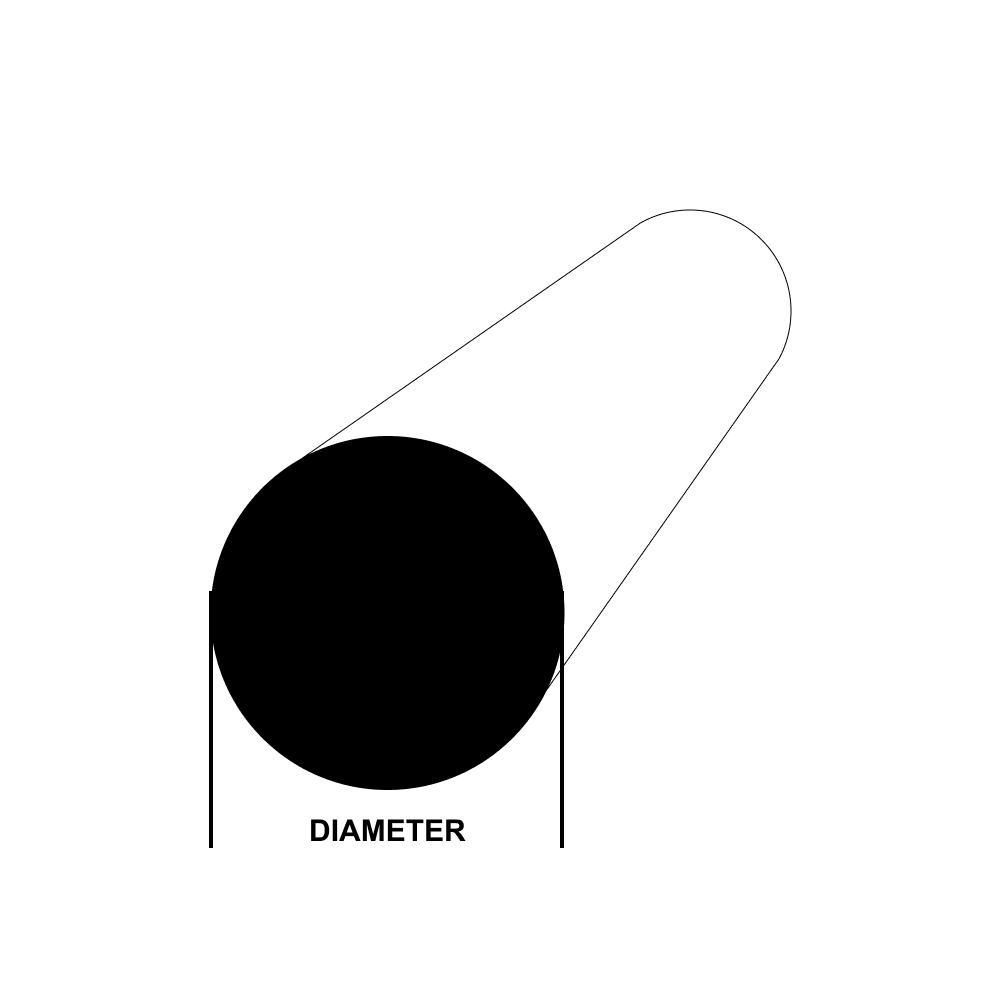

| Dimension Name | Specification |

| Diameter | 1.25 |

| Max Length | 144 |

| Alloy | Moldmax |

| Temper | High Hard |

| MTR Availability | Yes |

| Material | Beryllium Copper |

| Shape | Bar-Round |

| Custom Cut Warehouse | 1 |

| Weight/Lineal Foot | ||

| 4.45 pounds |

| Mechanical Properties | |

| Property | Value |

| Brinell Hardness 3000 kg load | 371 |

| Elongation % in 2 in. | 5 |

| Rockwell Hardness C Scale | 40 |

| Yield Tensile Strength KSI | 145 |

| Melting Point °F | 1600 min |

| Ultimate Tensile Strength KSI | 170 |

| Density g/cm^3 | 8 |

| Chemistry Information: Moldmax Beryllium Copper | |

| Element | Percentage |

| Cu | 97.95 |

| Be | 1.8 |

| Co | 0.25 |

| Cu | 98.2 |

| Be | 1.8 |

Continue modifying your quoted cart?

Continue modifying your quoted cart?