Accepting orders 24/7. We'll resume shipping on July 5th

Serving global customers with custom-cut metals and trusted delivery.

Have Specs Ready? Send Us Your RFP for a Fast, Competitive Quote.

Aluminum Rectangle Bar 2024-T351 offers an excellent strength-to-weight ratio, high fatigue resistance, and average machinability. The addition of copper to this alloy makes 2024 one of the strongest aluminum alloys, but it also is more susceptible to corrosion than most other aluminum alloys. 2024 is typically used in aerospace applications, clock parts, computer parts, hydraulic parts, bolts, valves, nuts, pistons, and gears.

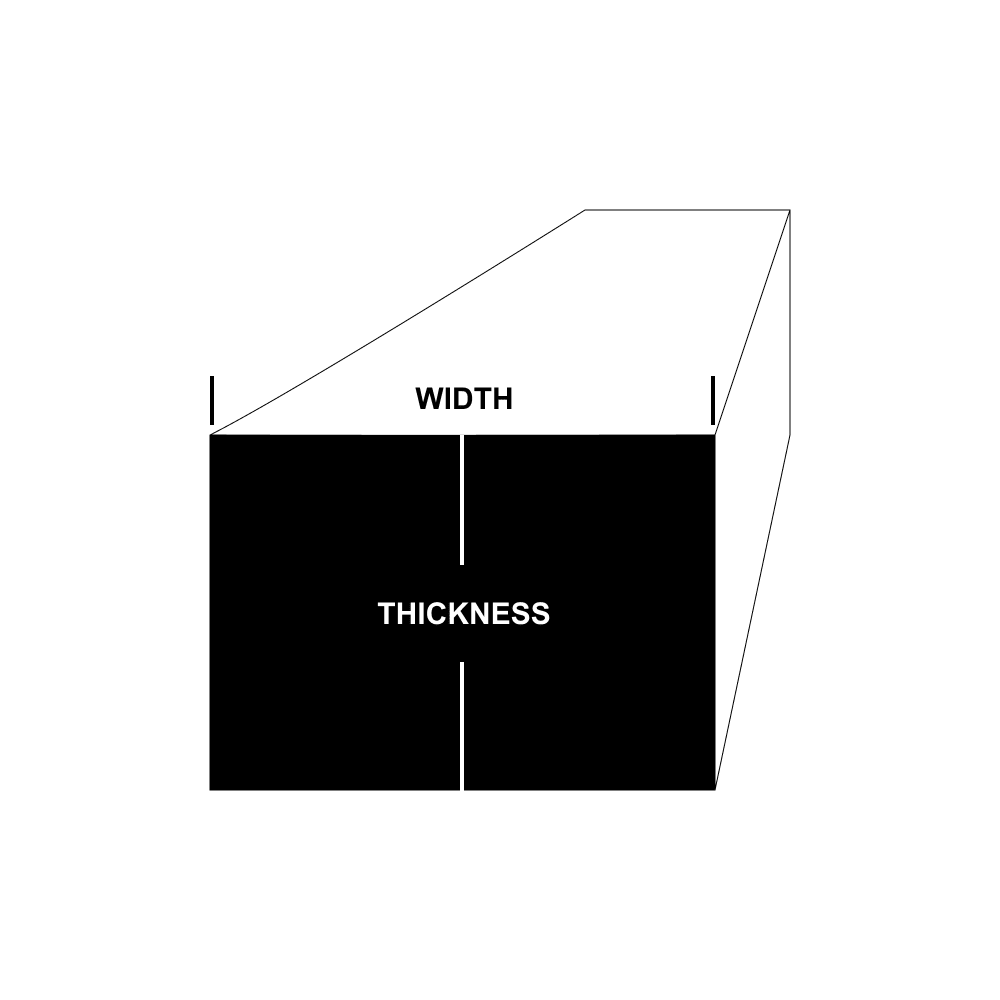

| Dimension Name | Specification |

| Thickness | 0.5 |

| Width | 4 |

| Max Length | 144 |

| Alloy | 2024 |

| Temper | T351 |

| Production Method | Cold Finished |

| Material | Aluminum |

| Shape | Bar-Rectangle |

| MTR Availability | Yes |

| RoHS | Yes 6C |

| REACH | No |

| Custom Cut Warehouse | 1 |

This material meets the following specs: ASTM- B211, AMS- 4120, AMS- QQ-A-225/6

| Weight/Lineal Foot | ||

| 2.44 pounds |

| Mechanical Properties | |

| Property | Value |

| Density g/cm^3 | 3 |

| Ultimate Tensile Strength KSI | 67 |

| Brinell Hardness 500 kg load | 120 |

| Yield Tensile Strength KSI | 47 |

| Elongation % in 2 in. | 13 |

| Melting Point °F | 935 - 1180 |

| Shear Strength KSI | 41 |

| Rockwell Hardness B Scale | 75 |

| Electrical Conductivity % IACS | 30 |

| Machinability % | 70 |

| Chemistry Information: 2024 Aluminum | |

| Element | Percentage |

| Al | 93.5 |

| Cr | 0.1 max |

| Cu | 3.8 - 4.9 |

| Mg | 1.2 - 1.8 |

| Fe | 0.5 max |

| Mn | 0.3 - 0.9 |

| Si | 0.5 max |

| Zn | 0.25 max |

| Ti | 0.15 max |